Researchers at the University of Birmingham have developed a groundbreaking new type of photocurable resin that offers significant advantages over traditional 3D printing materials.

The innovative resin is entirely bio-sourced, derived from lipoic acid, a naturally occurring fatty acid molecule. Unlike conventional resins, which often rely on petrochemical-based materials, this new material can be 3D printed, recycled, and then reprinted, creating a more sustainable and circular approach to 3D printing.

One of the key challenges in 3D printing is the difficulty in recycling printed objects. Traditional resins form irreversible bonds during the curing process, making recycling difficult. The new bio-sourced resin, however, can be broken down and recycled with minimal loss of material properties.

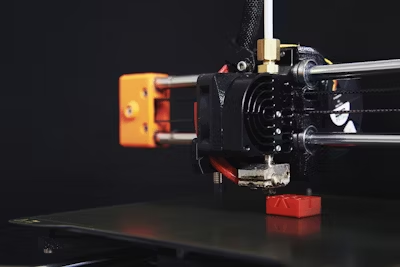

The resin is compatible with various 3D printing techniques, including DLP, SLA, and direct ink write (InkJet) printing. It offers high fidelity and resolution, making it suitable for a wide range of applications, such as sustainable packaging, rapid prototyping, and the production of optical and electronic devices.

Professor Andrew Dove, who led the research team, believes that this new material has the potential to revolutionize the 3D printing industry. By offering a more sustainable and circular solution, this innovation can contribute to a greener future.

The research team is continuing to explore the potential of this new material and is working to further optimize its properties and expand its applications.

Swanwick House, 22 Towcester Road, Old Stratford, Milton Keynes, MK19 6AQ, UK

© 2025 Project Management Global. All rights reserved | Privacy Policy